Category:

Plastic pipe machine

Product description:

Flat drip irrigation pipe production line

Technical parameter

|

Pipe diameter |

Pipe thickness |

Production speed |

Dripper space |

|

Φ12-16-20-22-25 |

0.12-0.4mm |

360m/min |

100、150、200、300、400、500、1000mm |

|

Dripper space |

Normal speed |

|

300mm |

360m/min |

|

200mm |

360m/min |

|

100mm |

300m/min |

Product Details

Core component equipment 1: Dripper screening device

Equipped with advanced dripper conveying and storage device, automatic dripper screening, 1500W screening motor, pneumatic centrifugal screening method, the conveying speed of dripper is more than 2000/min.

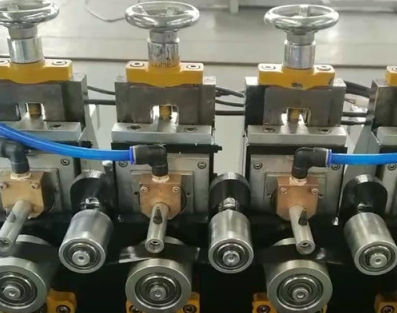

Core component equipment 2: Dripper conveying device

The rail is made of aluminum alloy by drawing, which ensures the smoothness of the dripper during high-speed transportation, and the vulnerable parts are easy to replace;

Imported AC servo motor is used to ensure the stability of dripper delivery;

The conveying device is controlled by the main control system to ensure that the distance between the drippers remains unchanged when the speed of the drip irrigation pipe changes.

Core component equipment 3: Single screw extrusion device

The machine head adopts a single-spiral structure, with uniform internal pressure, which improves the fluidity of plastics and the gloss of products and the uniformity of wall thickness, which is suitable for high-speed production of thin-walled pipes.

Core component equipment 4: Punching and online detection device

Fully automatic punching device, the maximum punching speed is more than 2600 pieces/min;

Equipped with an advanced online punching detection device, it can automatically detect the punching effect of the dripper, and timely detect the deviation, missed punching or no chips and alarm in time;

Real-time tracking and adjustment of the punching state through the PLC control screen.

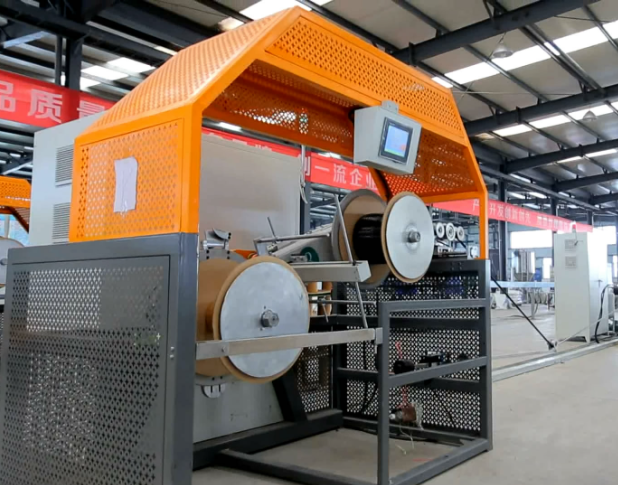

Core component equipment 5: Double-station automatic winding device

Automatically complete the winding, roll changing and switching of the drip irrigation pipe, and the maximum winding speed can reach 350 m/min;

Imported AC servo motor is used to ensure the stability of winding;

Control the operation through the PLC man-machine interface.

Name: Annie

Mobile:+86-15166699173 (whatsapp)

Tel:+86-532-88278277

Whatsapp:8615166699173

Email:admin@shichengsj.com

Add:NO.109 Jilin Road,Beiguan industrial zone, Jiaozhou, Qingdao, China

We chat